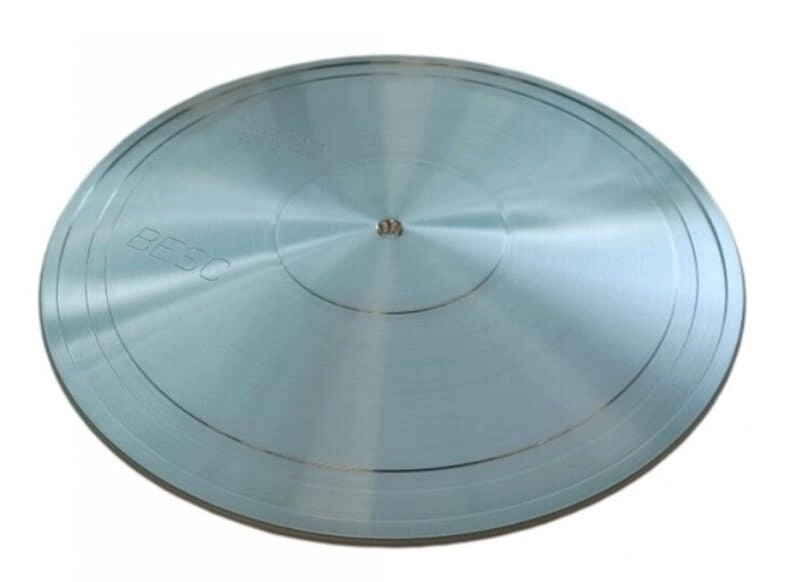

Model number: p-06

PVD Components

Film Stability × Yield Improvement

PVD (Physical Vapor Deposition) is a core thin-film technique in semiconductor and precision manufacturing. By physically evaporating or sputtering materials to form uniform coatings on wafers or workpieces, PVD improves surface conductivity, wear resistance, and protection.

Scientia supplies compatible PVD process components (process consumables & parts) to stabilize deposition quality and enhance yield.

Key Components & Functions

- Shield:Prevents chamber wall contamination, extending cleaning and maintenance intervals (MTBC).

- Collimator:Controls angular distribution of sputtered species, improving film uniformity and directionality.

- Cover Ring:Protects wafer edges, reducing unintended deposition and contamination.

- Deposition Ring:Defines deposition area and minimizes material waste.

- Shutter Disk:Blocks deposition during non-process steps to prevent contamination.

Applications

- Semiconductor manufacturing: Thin-film deposition, barrier/seed layers, and metallization in PVD processes.

- Precision coatings: Protective and functional layers for optoelectronics and high-reliability parts.