Model number: p-08

Etch Process Components

Non-Metal Parts|Corrosion Resistance × Precision Engineering

In semiconductor etching, non-metal components play a critical role in withstanding plasma environments, high temperatures, and corrosive gases, while maintaining process stability and accuracy.

Scientia provides a wide range of quartz (QTZ) and silicon (Si) parts, precisely manufactured to meet the stringent requirements of advanced etch processes.

Key Components & Functions

Curved Electrodes (Si)

Optimize plasma distribution, enhancing etch uniformity and process stability.

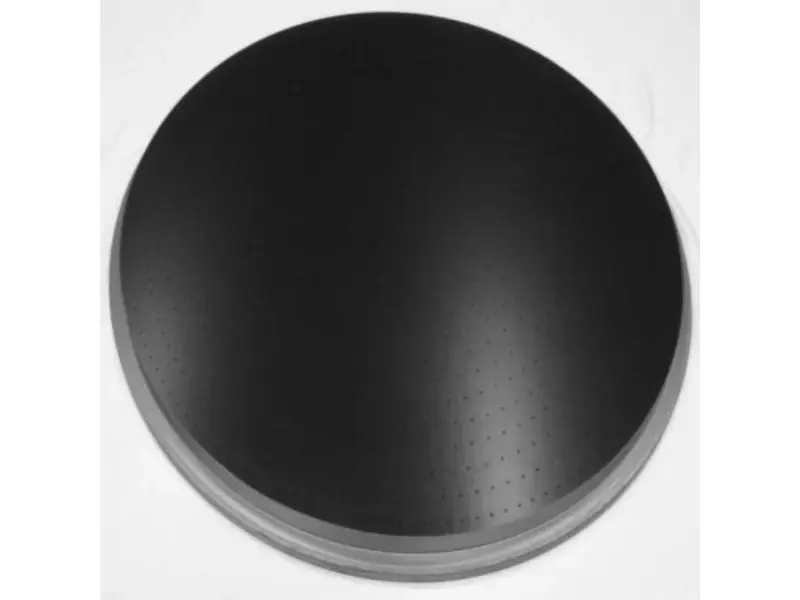

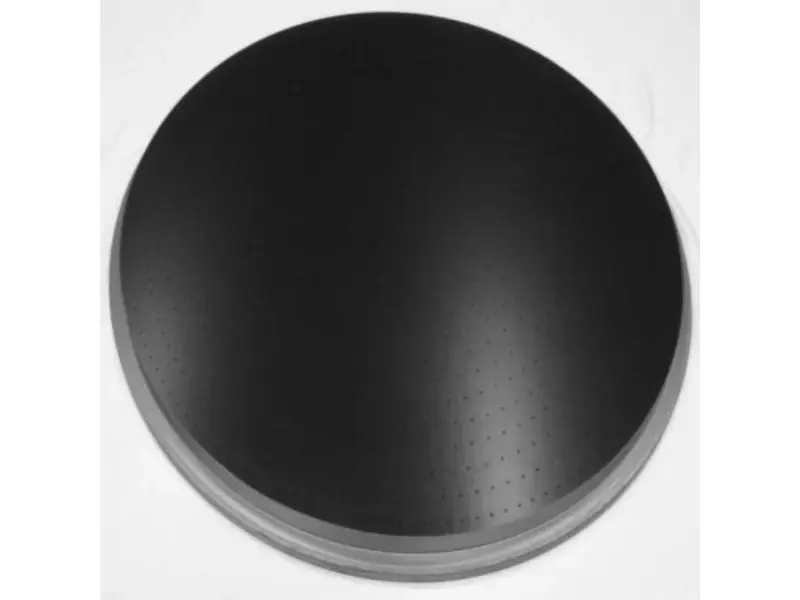

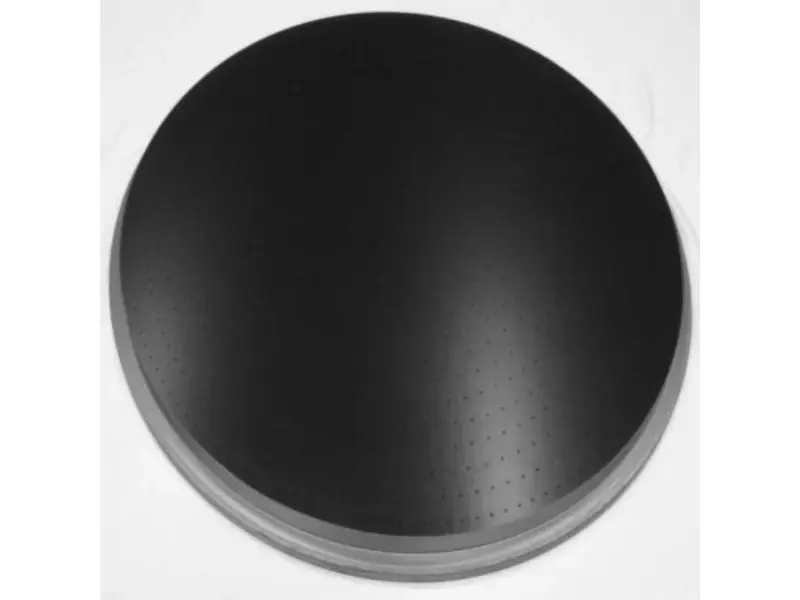

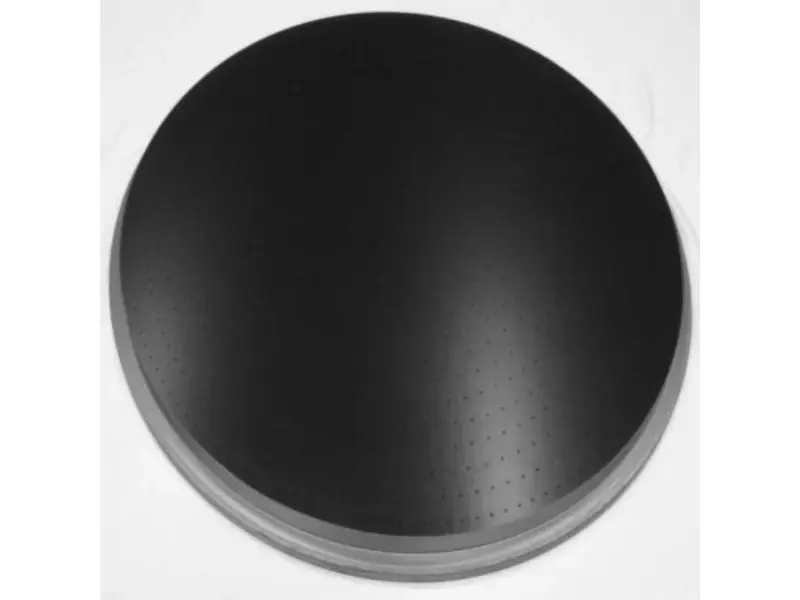

Planar Electrodes

Ensure stable electric fields and precise etching accuracy, improving pattern transfer quality.

Focus Rings (Si)

Concentrate electric fields and protect wafer edges, extending chamber and component lifetime.

Ground Rings (Si GND)

Provide stable grounding, maintaining process potential balance and operational safety.

QTZ Shields

High-temperature and corrosion-resistant quartz shields that prevent chamber contamination.

QTZ Insulators

Quartz parts with high insulation performance to block conductive paths, ensuring process stability and safety.

QTZ Disks

Quartz disks used for support or isolation of critical process areas.

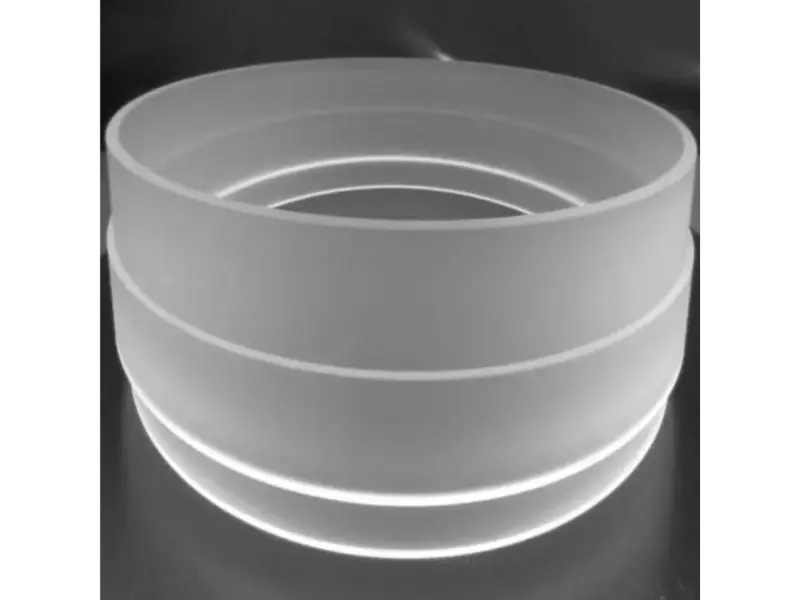

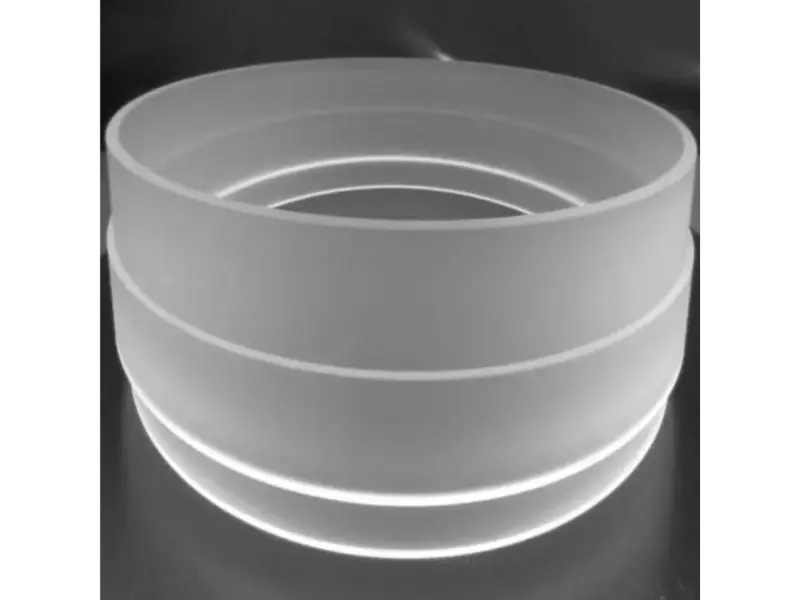

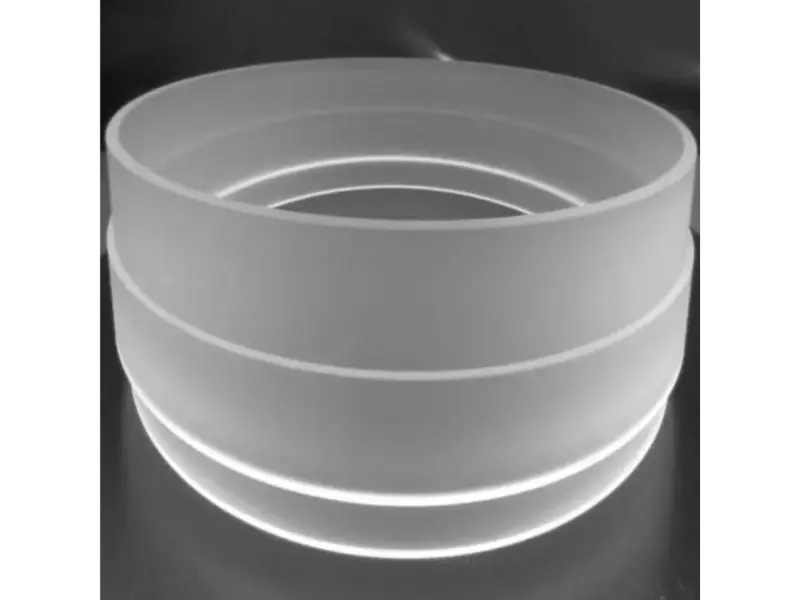

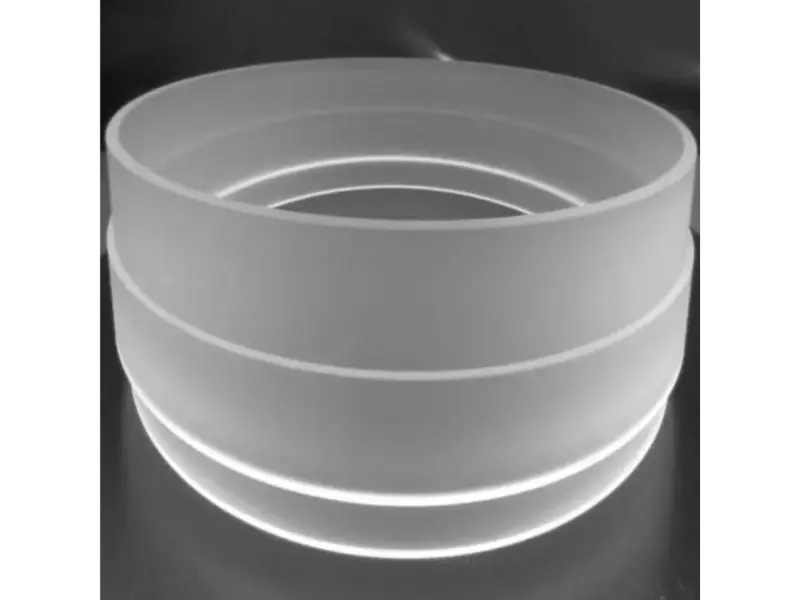

QTZ Rings

Maintain chamber gas flow and reaction uniformity.

Compatibility: Components are available in multiple sizes and specifications to fit a broad range of etch platforms.

Applications

- Semiconductor Etching: Critical non-metal consumables for advanced etch chambers.

- Process Stability: Improve uniformity, extend component lifetime, and safeguard chamber reliability.