Model number: p-09

Grinding Wheels

Wafer Grinding × High-Precision Processing

Scientia supplies grinding wheels designed for semiconductor wafers and precision component processing, fully compatible with leading equipment platforms such as DISCO, OKAMOTO, and TSK.

Each wheel can be tailored to customer process requirements, supporting a wide range of materials including silicon wafers, silicon carbide (SiC), gallium arsenide (GaAs), optical glass, and ceramics.

Key Features & Advantages

- Equipment Compatibility: Designed for mainstream systems such as DISCO, OKAMOTO, and TSK

- Wafer Size Support: Compatible with 8-inch and 12-inch production lines

- Material Versatility: Suitable for Si, SiC, GaAs, optical glass, ceramics, and more

- Multiple Grit Options: Diamond grit sizes available for both coarse and fine grinding stages

- Short Lead Time (~1 month): Supports quick production ramp-up and reduces mass-production timelines

Applications and Compatible Grinder Models

| O.D(mn) | Grinder Model | Mesh Size |

|---|---|---|

| 8 inch 202~204 |

DISCO(DFG840/8540...) (200mm) |

#325-#1200 |

| #2000-#3000 | ||

| #4000-#6000 | ||

| #8000~ | ||

| 8 inch 205 |

OKAMOTO(MK-II,VG502,GNX200...) TSK(PG200…) |

#325-#1200 |

| #2000-#3000 | ||

| #4000-#6000 | ||

| #8000~ | ||

| 12 inch 300~304 |

DISCO (DFG8560,DGP8760/8761....) OKAMOTO(GNX300...) TSK(PG300/PG3000...) |

#325-#1200 |

| #2000-#3000 | ||

| #4000-#6000 | ||

| #80000~ |

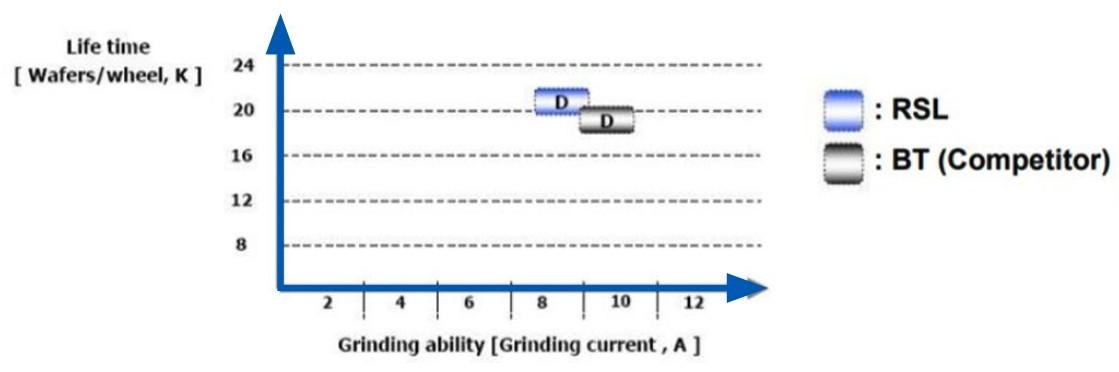

Grinding Wheel Performance Comparison

| Wheel Type | KFMI RSL | D company BT300 | |

|---|---|---|---|

| Specification | Bond type | Porous structure resin | Porous structure resin |

| Mesh size | #325 | #320 | |

| Performance | High easy grinding ability Longer life time than BT300 |

-Easy grinding and normal life time | |

| Grinding ability (max grinding current) |

8~9A | 9~10A | |

| Wheel Life | ~21000 pcs | ~19000 pcs | |

Looking for reliable grinding wheel solutions? Get in touch today for selection guidance and sample testing programs.